Understanding Elevator Pit Depth: Why It Matters in Modern Construction

Elevator pit depth is an important consideration when designing buildings that have vertical conveyance systems, and yet it is one component that is often overlooked or an afterthought. While it won’t be seen by most users, what happens below ground is just as important as the lift car and its components above. Fitting the elevator pit is not only conducive to safety, performance, and compliance with a construction project, it is also integral to the elevator pit’s form and function. Whether high-rise, low-rise, commercial, or residential, awareness of pit depth is critical to the design of a dependable and efficient lift system.

What Is Elevator Pit Depth?

To put it simply, elevator pit depth is the vertical distance from the lowest floor level to the bottom of the elevator shaft and can accommodate different lift components, very important components such as buffers, counterweights, hydraulic systems or electrical panels; it all depends on the types of lifts being installed.

This depth needs to be carefully measured and constructed. It allows for when the lift goes to full descent or, in the case of an emergency, there is a buffer zone to dissipate the impact. The elevator pit depth is intended to not only protect the lift and its passengers but also ensure consistent safe operation over the lifetime of the lift. The elevator shaft dimensions and lift shaft size must be coordinated with the depth to ensure all systems operate smoothly and safely.

Why Pit Depth Matters in Construction

An incorrectly sized elevator pit can result in a number of issues, from safety hazards to non-compliance with building regulations. If the pit is too shallow, there is a risk that emergency buffer systems won’t function as intended. This can endanger the lift and compromise passenger safety.

From a construction perspective, proper elevator pit depth makes installation easier and allows for future lift maintenance without excessive modifications. It also impacts the type of elevator system that can be used. A hydraulic lift for example, often requires more space underneath than a traction lift. By ensuring the right pit depth from the start, costly alterations down the line can be avoided.

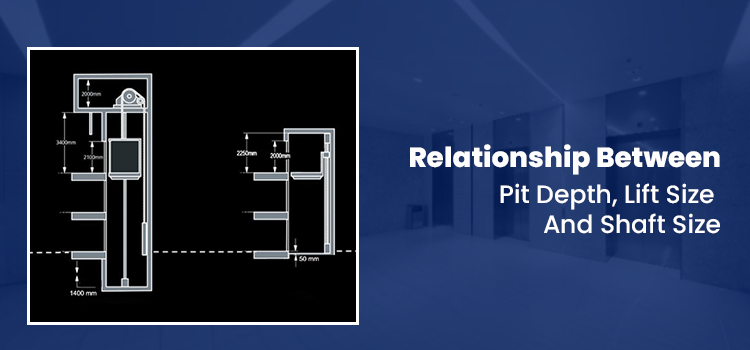

Relationship Between Pit Depth, Lift Size, and Shaft Size

The lift size and lift shaft size go hand in hand with elevator pit depth. Larger lifts, especially those designed for freight or high occupancy, need deeper pits to accommodate the bigger buffers and heavier counterweights. On the other hand, smaller residential lifts might require less space but still need to comply with minimum standards.

It is a delicate balance; going too deep can add unnecessary construction costs, while going too shallow might limit the type of elevator that can be installed. Moreover, shallow pits can restrict the vertical travel of the lift or lead to discomfort during operation due to limited shock absorption.

In essence, elevator pit depth isn’t a one-size-fits-all figure. It changes based on the elevator shaft dimensions, the weight of the elevator, and how many people or how much cargo it is expected to carry. Engineers must assess the entire lift system, including expected traffic, ride comfort, and emergency stopping requirements. Getting this balance right ensures the elevator operates smoothly, safely, and efficiently across its full range of motion.

Special Cases: Shallow Pits and Pitless Elevators Planning Ahead:

While standard pits are the norm, some building designs require alternatives. For example, heritage buildings, basements with high water tables, or retrofits in existing structures may not allow deep excavation.

In such cases, shallow pits or pitless elevators come into play. These systems use innovative designs to minimize the need for depth, often relying on mechanical or architectural solutions like shorter buffers or overhead mechanisms to maintain safety and functionality. Although they are not suitable for all the buildings, they offer flexibility where traditional pits are impractical.

However, shallow-pit solutions usually have limitations in terms of lift size and speed. They may also require more frequent lift maintenance due to the compact configuration of components. Designers must also consider whether the building can accommodate the required overhead clearance. These elevators can be a smart solution for constrained spaces, but careful planning is needed to meet the safety codes and long-term usage expectations.

How Architects and Engineers Can Optimize Pit Depth

Smart design starts at the drawing board. For architects and engineers, early planning of elevator pit depth ensures everything from safety compliance to operational efficiency. Here are some tips for getting it right:

1. Collaborate with Lift Specialists Early

Include elevator contractors or consultants during the initial planning stages. They can recommend the appropriate pit depth based on the type of lift under consideration and the building’s purpose.

2. Consider Future Maintenance

Always factor in access for technicians. Making the pit too cramped can lead to difficulties during repairs or routine checks, increasing the cost and effort of lift maintenance.

3. Check Local Codes and Regulations

Different regions have specific rules around elevator installation. Complying with standards like ASME or EN 81 ensures both safety and legal approval.

4. Coordinate with Structural Engineers

The elevator shaft dimensions and overall lift shaft size need to align with pit depth. This coordination helps avoid any misalignment during construction or installation.

5. Plan for Drainage and Waterproofing

Since the pit is below ground level, it’s prone to moisture buildup. Proper waterproofing and a reliable drainage system are must-haves to prevent component damage.

Conclusion

Even though it lies beneath the floor, elevator pit depth is one of the most important elements of lift design and construction. It directly influences the safety, performance and long-term durability of the elevator system. By understanding how pit depth interacts with lift size, lift shaft size, and elevator shaft dimensions, designers can build smarter, safer, and more efficient vertical transportation systems.

Incorporating the right pit depth not only supports smoother day-to-day operation but also simplifies future lift maintenance. Whether you are dealing with standard shafts or planning around limitations with shallow pits, the key lies in thoughtful design and collaboration with experienced professionals such as MAS Industries.

FAQ’s

1. How deep should an elevator pit be?

The depth varies by elevator type but usually ranges between 8 and 10 feet. Deeper pits may be required for high-speed or heavy-duty lifts.

2. What is the average depth of an elevator?

On average, a standard lift has a depth of about 6 feet. However, the final measurement depends on the system’s size and specifications.

3. What is the minimum size for a lift pit?

The minimum pit depth is typically determined by local codes and the type of lift used. It’s often around 36 inches, but this can differ based on the lift size and load capacity.

4. What is the elevator pit?

An elevator pit is the space at the bottom of the elevator shaft. It contains essential components like buffers, counterweights, and, in some cases, hydraulic and electrical systems. It’s designed for safety, support and system management.

Leave a Reply