How does a pulley-based elevator system work?

In the present era, many elevators operate on diverse mechanisms. Among these mechanisms, pulleys enable the elevator to run smoothly. So, to know more about the engineering marvels, you have to comprehend the function of the pulleys. In that case, scroll through this article to know more about elevator pulley systems.

What is an Elevator Pulley System?

An elevator pulley system lifts and lowers the elevator. Such a type of system operates through a series of pulleys, cables, and counterweights. Primarily, the system reduces the force needed to move the elevator. This is accomplished by distributing the weight of the elevator’s car and the passengers. Once the motor drives the pulleys, the cables connected to the lift move. Moreover, the lifting process is more efficient when the counterweights help balance the car’s weight.

What are the key components of an elevator pulley system?

An elevator pulley system comprises many components. Let’s check the components in detail.

Motor

The motor is a component that provides power to the elevator. This enables the lift to move up or down vertically across the building.

Pulleys

When you observe the pulleys, these support the cables. They are crucial to changing the direction of the movement and ensuring smooth operation.

Cables

Cables transfer the force from the motor to the elevator car and the counterweights. These cables are usually made from steel and are known for their strength. But, the way in which cables work depends on the elevator’s cabin design.

Counterweights

Counterweights are usually used to balance the elevator car’s weight. Such weights further reduce the energy needed to lift the elevator’s car. Thus, the system becomes more efficient.

Sheaves

Sheaves are nothing but specialized pulleys that guide the cables. These are often present in the machine room of an elevator.

Guide Rails

Guide rails ensure that the elevator moves smoothly in the vertical direction. As the rails offer support, it also keeps the lift stable while it’s in motion.

Brake System

The brake system helps to stop the elevator and keep it in its place. This system, thus, ensures safety when the elevator is stationary.

Controller

The controller, present in the system, directs the motor and leads the lift depending on the user’s input.

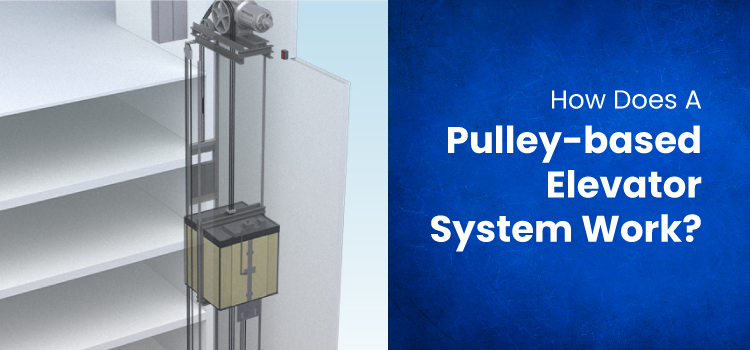

How does a Pulley Elevator System Work?

A pulley elevator system usually operates through a set of pulleys, cables, and a counterweight. Such a system then lifts and lowers the elevator’s car. As soon as the motor is activated, it drives the pulley present at the top of the shaft. Later, the cables, which are attached to the counterweight and the elevator car, move smoothly. Once the pulley starts turning, the cables raise or lower the elevator’s car. On the other hand, the counterweight moves in the opposite direction. This helps to balance the load ahead. Besides, the counterweight also reduces the energy required to lift the elevator’s car.

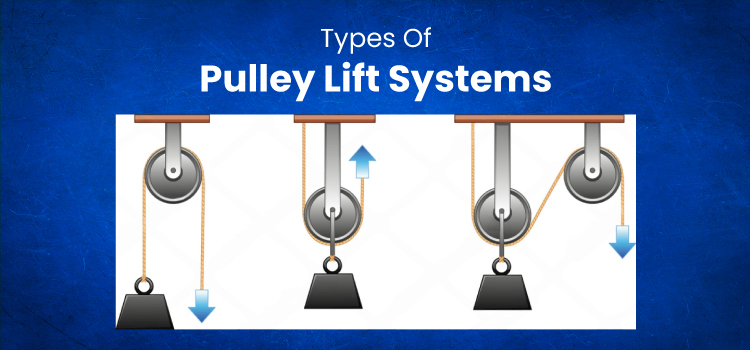

Types of Pulley Lift Systems

In today’s world, you will come across several pulley lift systems. Every type of system is designed to suit the building requirements and operational needs.

Traction Pulley System

This pulley system is one of the most common systems in modern buildings. As the pulley system relies on a motor-driven pulley, the cables move at a certain pace. The system later becomes energy-efficient when the counterweight balances the elevator car’s weight.

Moveable Pulley System

Moveable pulley systems are also commonly used in lifts. When you come across this system, one end of the rope is fixed. But, the pulley can move along the rope’s length. As the lift moves, the pulley changes its position. This helps in redistributing the load when the lift is moving.

Fixed Pulley System

Such a system is not usually found in modern lifts. But, the system plays a role in offering support. Moreover, the stationary pulleys distribute the load and prevent strain on every component.

Benefits of an Efficient Pulley Elevator System

There are many benefits of an efficient pulley elevator system. Let’s check these ahead.

Energy Efficiency

As the counterweight balances the weight of the elevator’s car, it reduces the energy consumption. This makes the operation more energy-efficient. The operational costs also get reduced due to the pulley elevator system.

Smooth Operation

An efficient pulley system reduces friction and ensures smooth movement. This results in a comfortable ride for the passengers.

Safety

An optimized pulley system helps maintain precise control over the elevator’s movement. Additionally, the counterweight system ensures stability. Hence, the individuals don’t have to worry about sudden jolts or an imbalance.

Cost Savings

An efficient pulley system can significantly reduce the operational costs in the long run. This means that the building owner will not have to worry about frequent maintenance. Even when the elevator is used often, individuals will experience less breakdowns.

Challenges and Maintenance of Pulley Elevator Systems

Pulley elevator systems are quite efficient and reliable. But, many challenges may arise with such systems. Way ahead, these systems have to undergo regular maintenance as well. So, let’s check the common challenges and how to maintain the systems.

What challenges do people face with pulley elevator systems?

- With time, the cables used in the pulley systems can wear out. The worn out cables can further become weak and break all of a sudden. But, regular inspection can help to prevent sudden failures.

- While the motor is driving the pulley system, it can get overheated. In case there are any issues with the gearbox or the motor, then it can lead to erratic elevator movement. Considerable energy will also be consumed when the lift is moving.

- If the pulleys are not aligned properly, the cables may slip or rub. Misalignment can then lead to damage or inefficient operation. The issue can also increase the likelihood of system failure.

- Pulleys, cables, and motors are susceptible to numerous environmental conditions. Factors like humidity and temperature fluctuations can cause rust and corrosion. This issue may prevail in case the systems are not properly maintained.

- Using the elevator beyond its usual capacity can affect the pulley system. As a result, premature failure of the key components may be observed in the future.

How to maintain the elevator pulley systems?

- Routine inspections are essential to ensure proper functioning of the main components. This includes checking the cables for wear and tear and inspecting the pulleys.

- After some time, the key components also have to be lubricated properly. Lubricating the parts will thus reduce friction and prevent premature wear out. The system will also run smoothly when the lift is used often.

- Depending on the level of wear out, the cables must be replaced periodically. Once the cables are replaced, the system will not malfunction.

- To ensure smooth operation, the pulleys and the cables have to be properly aligned. In case there’s any misalignment, then uneven wear out can be reduced through recalibration. Regular checks can also help to prevent prominent issues.

- As technology evolves, upgrading the pulley system can enhance efficiency and overall performance. Moreover, when the motor and the control systems are upgraded, the pulley system will work properly.

- Eventually, the components of the pulley system have to be cleaned carefully. In case dirt has accumulated on the diverse components, then it can cause mechanical failures. Accumulation of dirt can also lead to overheating after a time span.

Conclusion

Finally, pulleys enable elevator systems to function properly. These also facilitate smooth motion of lifts as they move vertically. In fact, the pulley systems contribute to the seamless transportation of various lifts.

Are you still looking for a reliable lift manufacturer for your clients? Well, in such a case, you can connect with MAS Industries among elevator companies in Mumbai. Even when we embrace technology for the lifts we manufacture, we assure quality. Our team manufactures products as per the European standards. Compliance with the European Directive 2014/33/EU is also ensured during the manufacturing phase.

Leave a Reply